Thursday, 10 December 2015

Reason for failures of paints?

1. Not proper cleaning of body before painting

2. Not covering dents or spots

3. Not using of proper good quality paint

4. Not applied the pretreatment with zinc phosphate

Requirements of Good Painting?

2. It should protect the hidden parts also from the corrosion.

3. It should have esthetic appearance.

4. It should be smooth finish for stream lining.

5. It must reduce the aerodynamic drag.

Automotive Painting

The corrosive nature of a metal used in a motor body

construction, necessitate the application of an anti corrosion coating. For this

reason the painting should be done.

Function of Painting:

1. It reduces the corrosion and protect the vehicle

body.

2. It is used for cleanliness.

3. It is used for esthetic appearance.

4. It is used to reduce the friction due to the

aerodynamic drag and allow the vehicle in stream

lining.

5. It is used for identification purpose.

Tuesday, 1 December 2015

Different methods to door lock or unlock mechanisms?

There are different methods to door lock or unlock mechanisms:

1. With a key

2. By pressing the unlock button inside the car

3. By using the combination lock on the outside of the door

4. By pulling up the knob on the inside of the door.

5. With a keyless – entry remote control.

6. By a signal from a control center.

1. With a key

2. By pressing the unlock button inside the car

3. By using the combination lock on the outside of the door

4. By pulling up the knob on the inside of the door.

5. With a keyless – entry remote control.

6. By a signal from a control center.

Torsion Bar in suspension system?

Torsion Bar

Torsion bar suspension is used in independent suspension system. It is a

rod acting in torsion and taking shear stresses only. It is made up of heat

treated alloy spring steel. This bar stores amount of energy nearly as same as

coil spring.

The bar is fixed at one end to the fr4ame, while the other end is fixed to

the end of the wheel arm and supported in the bearing. The other end of the

wheel arm connected to the wheel hub. When the wheel strikes a bump, it

starts vibrating up and down, thus exerting torque on the torsion bar which

acts as a spring.

Stabilizer Bar in suspension system?

Stabilizer is necessarily used in all independent front suspension. It

reduces tendency of the vehicle to roll on either side when taking a turn. It is

simply a bar of alloy steel with arms at each end connected to the lower wish

bone of the independent suspension system. It is supported in bush bearings

fixed the frame and is parallel to cross member. When both the wheels

deflect up or down by the same amount, the stabilizer bar simple turns in the

bearings. When only one wheel deflects, then only one end of the stabilizermoves, thus it acts as a spring between two sides of the independent front

suspension.

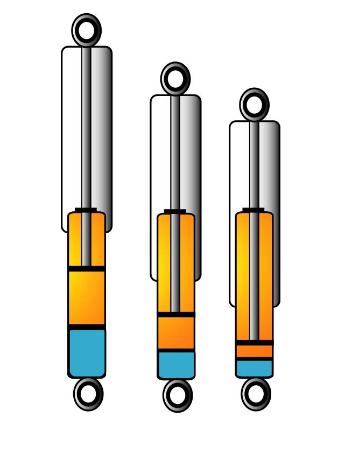

Working of Single acting Telescopic hydraulic shock absorbers?

If the axle eye moves upwards then the fluid must be displaced

from the bottom. Top side of the bottom side fluid through the outer ring of

the piston by lifting the non return valve. But since the increase in the volume

of upper end of the cylinder is less than the volume of the lower end. Fluid will

also displaced through the inner ring of holes of non return valve of foot

valve, and the level at the fluid will raise in the reservoir. The pressure setup will

depend on the size of hole in the piston and Foot valve and the squire of the

speed of which the cylinder is moved.

For downward motion of the cylinder the fluid will be displaced form

the upper end of the piston. In the leaver end through the inner ring of hole of

non return valve in the piston. The fluid will also be draw in the lower end of

the cylinder from the reservoir to the outer ring of hole of non return valve of

the foot valve.

Fig of shock absorber

Need of Shock Absorber?

If the suspension springs are rigid enough, they will

not absorb road shocks efficiently, and if they are flexible enough, they will

continue to vibrate for longer time even after the bump has passed.

Therefore, the springing device must be compromise flexibility and stiffness a

shock absorber needed in Automobile Suspension system.

Helper Springs?

The helper springs are used in heavy vehicles for rear suspension. When

vehicle fully loaded the main spring as well as helper spring to come in

action and absorb the road shocks. When the load of the vehicle is less the

helper spring will not act and the main spring only absorb the road shocks.

Sunday, 29 November 2015

What is meant by Full elliptic leaf springs?

The advantage of this type is the elimination of shackle and spring. The lubrication and wear frequently which are on of the main draw back of this type of springs.

Types of Leaf Springs?

There are five types of leaf springs

1. Full – elliptic type

2. Semi – elliptic type

3. Three Quarter – elliptic type

4. Transverse Spring type

5. Helper Spring type

1. Full – elliptic type

2. Semi – elliptic type

3. Three Quarter – elliptic type

4. Transverse Spring type

5. Helper Spring type

Types of suspension springs?

1. Steel Springs :

a. Leaf Springs

b. Coil Springs

c. Torsion bar Springs

2. Rubber Springs:

a. Compression Springs

b. Progressive Springs

3. Plastic Springs

4. Air Springs:

a. Bellow Type

b. Pestoon Type

5. Hydraulic Type

What are the basic suspension movements?

1. Bouncing:

The vertical movement of the complete body.

2. Pitching:

The rotating movement of all the parts between the spring and road and the portion of spring weight itself.

3. Rolling:

The movement about longitudinal axis produced by the centrifugal force during cornering.

The vertical movement of the complete body.

2. Pitching:

The rotating movement of all the parts between the spring and road and the portion of spring weight itself.

3. Rolling:

The movement about longitudinal axis produced by the centrifugal force during cornering.

What is meant by Sprung Weight and un Sprung Weight?

Sprung Weight:

It is weight of all the parts supported by the spring including weight of the spring.

Un sprung weight:

It is the weight of all the parts between the spring and rod and the portion of spring weight it self.

Advantages of Suspension system?

1. It provides softer suspension.

2. It reduces wheel wobbling.

3. It reduces the tendency of fitting of the wheel on one side due to road vibration.

4. It provides more space for engine accommodation.

5. It promotes under steer which results low un sprung weight.

6. The movement of the spring on one wheel is not transmitted to the other wheel.

What is meant by Independent suspension system?

The independent suspension system means

any arrangement that connects road wheels to the frame in which raise or

fall of the wheel has no direct effect on the other wheel. It eliminates wheel

wobbling.

What are the main Components of Suspension system?

That are the very main components of suspension system.

Thursday, 26 November 2015

What are the Functions of suspension system?

1. It prevents the vehicle body and frame from road shocks.

2. It gives stability of the vehicle.

3. It safeguards the passengers and goods from road shocks.

4. It gives the good road holding while driving, cornering and braking.

5. It gives cushioning effect.

6. It provides comfort.

2. It gives stability of the vehicle.

3. It safeguards the passengers and goods from road shocks.

4. It gives the good road holding while driving, cornering and braking.

5. It gives cushioning effect.

6. It provides comfort.

Advantages of air brake?

1. This system used in heavy vehicles because they are more powerful than hydraulic or mechanical brakes.

2. It simplifies the chassis design

3. The compressed air is used for purposes like tyre inflation; for horn, windscreen wiper etc.

What is meant by Air Brake System?

The air brake system consists of two-stage air-compressor driven by the

crankshaft or gearbox shaft. It takes air from atmosphere, compresses it and

delivers to the air reservoir through un-loader valve. Where the pressure of

the reservoir reaches the maximum degree, the un- loader valve opens to the

atmosphere. Then the compressed air is directed in to the atmosphere

directly.

What is meant by WHEEL CYLINDER?

Wheel cylinder is the second important hydraulic brake

system. It consists of two pistons which can move in opposite directions by the

fluid pressure. It is rigidly mounted on the brake shield or backing plate. The

boots protect the cylinders from foreign substances. Bleeder valves are

provided in the cylinder to permit air and liquid to be pumped out of the

system during of the bleeding operation .

Piston cup fits tightly in the cylinder against each piston and seal themechanism against leakage of the brake fluid. A Spring serves to hold the

cups against the piston when the pressure is decreased.

When the brakes are applied the brake fluid enters the cylinder from a

brake line connection inlet between the two pistons. It causes to force out

the two pistons in opposite directions. This motion is transmitted to the brake

shoe. Directly or through links force them against the brake drum, thus

applying the brake.

Wednesday, 25 November 2015

What is meant by master cylinder in braking system?

Master Cylinder:

The Master Cylinder is the heart of the hydraulic brake

system. It consists of two main chambers. The fluid reservoir which contains

the fluid to supply to the brake system, and the compression chamber in

which the piston operates. The reservoir supplies fluid to the brake system

through two ports.

Main components of drum brakes?

1. Brake drum

2. Back plate

3. Brake shoes

4. Brake Liners

5. Retaining Springs

6. Cam

7. Brake Linkages

What are the Types of Mechanical Brakes?

a. Drum Brakes (Internal Expanding or External Contracting)

b. Disc Brakes (Single or Two caliper)

What are the Classification of Brakes?

1.By method of power

a) Mechanical brakes

b) Hydraulic brakes

c) Vacuum brakes

d) Air brakes

e) Electrical brakes

f) Magnetic brakes

g) Air assisted hydraulic brakes

2.By method of application:

a) Service or foot brakes

b)Parking or hand brakes

3.By method of operation:

a) Manual

b) Servo

c) Power operation

4. By method of Braking contact

a. Internal Expanding Brakes

b. External Contracting Brakes.

5. By Method of Applying Brake force:

a. Single Acting Brakes.

b. Double Acting Brakes.

a) Mechanical brakes

b) Hydraulic brakes

c) Vacuum brakes

d) Air brakes

e) Electrical brakes

f) Magnetic brakes

g) Air assisted hydraulic brakes

2.By method of application:

a) Service or foot brakes

b)Parking or hand brakes

3.By method of operation:

a) Manual

b) Servo

c) Power operation

4. By method of Braking contact

a. Internal Expanding Brakes

b. External Contracting Brakes.

5. By Method of Applying Brake force:

a. Single Acting Brakes.

b. Double Acting Brakes.

What are the Requirements of Automobile Brakes?

1.It should work efficiently irrespective of road condition and quality.

2.The retardation must be uniform throughout its application.

3.The pedal effort must be within the convenient capacity of the driver.

4.It must be reliable and should not be effected by heat water and dust.

5.It should be in minimum weight.

6.It should have long life.

7.It should be easy to maintain and adjust.

8.Noise and vibrations are to be minimum.

9.There should be provision for secondary brake or parking brake.

What are the function of brake?

1.It is used to stop the vehicle.

2.It is used to control the speed where and when required.

3.It is used to control the vehicle while descending along the slope.

4.To park the vehicle and held it in stationary position without the presence of Driver.

What is meant by Irreversible steering?

If the front road wheels does not transfer any deflection

to the steering which is called irreversible steering. After negotiating a curve

and the steering wheel not returned easily, there causes the production of undue stresses on the steering mechanism, therefore some degree of

irreversible also desired.

What is meant by Toe in and Toe out?

Toe-in:

It is the amount in minimum at the front part of the wheel points inwards approximately 3 to 5 mm. It prevents side slipping excessive tyre wear, proper rolling of front wheels and steering stability.

Toe-out:

It is the difference in angles between two front wheels and vehicle frame during turning. It is used to prevent dragging of tyre during turn.

It is the amount in minimum at the front part of the wheel points inwards approximately 3 to 5 mm. It prevents side slipping excessive tyre wear, proper rolling of front wheels and steering stability.

Toe-out:

It is the difference in angles between two front wheels and vehicle frame during turning. It is used to prevent dragging of tyre during turn.

what is meant by King-pin inclination?

It is the angle between vertical line to the king pin axis.

The inclination tends to keep wheels straight ahead and make the wheels to

get return to the straight position after completion of a turn. The inclination is

normally kept 7º to 8º.

what is meant by camber?

The angle between wheel axis to the vertical line at the top is called camber angle. It is approximately ½º to 2º.

What is meant by Caster Angle?

This is the angle between backward or forward tilting of the

king pin from the vertical axis at the top. This is about 2º to 4º. The backward

tilt is called as positive caster. The forward tilt is called negative caster.

what are the Factors effects the wheel alignment?

1. Factors pertaining to wheel:-

a. Balance of wheels(Static and Dynamic)

b. Inflation of tyre.

c. Brake adjustments.

2. Steering Linkages.

3. Suspension System

4. Steering Geometry –a. caster b. camber c. king pin inclination d. toe-in and toe-out etc., Steering Geometry: It refers to the angular relationship between the front wheels and parts attached to it and car frame. The steering Geometry includes

a. Caster angle

b. Camber angle

c. King-pin inclination

d. toe-in 5. toe-out etc.,

What are the Types of steering Linkages?

1. Conventional steering Linkage.

2. Direct cross type steering linkage

3. Three piece steering linkage

4. center arm steering linkage

5. Relay type steering linkage

What are the Functions of Steering Gear Box?

1. It converts the Rotary movement of the steering wheel in to the angular turning of the front wheels.

2. It also multiplies drivers efforts and give MECHANICAL ADVANTAGE

Types of Steering Gear Boxes?

1. Worm and Wheel Steering Gear.

2. Worm and Roller Steering Gear.

3. Re-circulating Ball type Steering Gear.

4. Rack and Pinion type Steering Gear.

5. Cam and Roller Gear type Steering Gear.

6. Cam and Peg Steering Gear.

7. Cam and Double lever Steering Gear.

8. Worm and Sector Type Steering Gear.

What are the main components of steering system?

1. Steering Wheel

2. Steering column or shaft

3. Steering Gear

4. Drop Arm or Pitman Arm

5. Drag Link

6. Steering Arm

7. Track-Arms

8. Track Rod or Tie-Rod

9. Adjusting Screws

2. Steering column or shaft

3. Steering Gear

4. Drop Arm or Pitman Arm

5. Drag Link

6. Steering Arm

7. Track-Arms

8. Track Rod or Tie-Rod

9. Adjusting Screws

Functions of Steering System?

1. It helps in swinging the wheels to the left or right.

2. It helps in turning the vehicle at the will of the driver.

3. It provides directional stability.

4. It is used to minimize the tyre wear and tear.

5. It helps in achieving self-centering efforts.

6. It absorbs major part of the road shocks.

2. It helps in turning the vehicle at the will of the driver.

3. It provides directional stability.

4. It is used to minimize the tyre wear and tear.

5. It helps in achieving self-centering efforts.

6. It absorbs major part of the road shocks.

REQUIREMENTS OF BODIES FOR VARIOUS TYPES OF VEHICLE?

The body of the most vehicle should fulfill the following requirements:

1. The body should be light.

2. It should have minimum number of components.

3. It should provide sufficient space for passengers and luggage.

4. It should withstand vibrations while in motion.

5. It should offer minimum resistance to air.

6. It should be cheap and easy in manufacturing.

7. It should be attractive in shape and colour.

8. It should have uniformly distributed load.

9. It should have long fatigue life.

10.It should provide good vision and ventilation.

1. The body should be light.

2. It should have minimum number of components.

3. It should provide sufficient space for passengers and luggage.

4. It should withstand vibrations while in motion.

5. It should offer minimum resistance to air.

6. It should be cheap and easy in manufacturing.

7. It should be attractive in shape and colour.

8. It should have uniformly distributed load.

9. It should have long fatigue life.

10.It should provide good vision and ventilation.

what are the loads acting on frame in automobile?

Various loads acting on the frame are,

1. Short duration Load - While crossing a broken patch.

2. Momentary duration Load - While taking a curve.

3. Impact Loads - Due to the collision of the vehicle.

4. Inertia Load - While applying brakes.

5. Static Loads - Loads due to chassis parts.

6. Over Loads - Beyond Design capacity.

1. Short duration Load - While crossing a broken patch.

2. Momentary duration Load - While taking a curve.

3. Impact Loads - Due to the collision of the vehicle.

4. Inertia Load - While applying brakes.

5. Static Loads - Loads due to chassis parts.

6. Over Loads - Beyond Design capacity.

TYPES OF CHASSIS FRAMES?

FUNCTIONS OF THE CHASSIS FRAME?

1. To carry load of the passengers or goods carried in the body.

2. To support the load of the body, engine, gear box etc.,

3. To withstand the forces caused due to the sudden braking or acceleration

4. To withstand the stresses caused due to the bad road condition.

5. To withstand centrifugal force while cornering

2. To support the load of the body, engine, gear box etc.,

3. To withstand the forces caused due to the sudden braking or acceleration

4. To withstand the stresses caused due to the bad road condition.

5. To withstand centrifugal force while cornering

Main components of the Chassis?

1. Frame: it is made up of long two members called side members

riveted together with the help of number of cross members.

2. Engine or Power plant: It provides the source of power.

3. Clutch: It connects and disconnects the power from the engine fly wheel to the transmission system.

4. Gear Box

6. Propeller Shaft

7. Differential

2. Engine or Power plant: It provides the source of power.

3. Clutch: It connects and disconnects the power from the engine fly wheel to the transmission system.

4. Gear Box

6. Propeller Shaft

7. Differential

Sunday, 22 November 2015

What is mean by Suspension System in automobile?

Suspension system of an automobile separates the wheel and axle assembly of the

automobile from its body. Main function of the suspension system is to isolate the

body of the vehicle from shocks and vibrations generated due to irregularities on

the surface of roads. Shock absorbers are provided in the vehicles for this purpose.

It is in the form of spring and damper. The suspension system is provided both on

front end and rear end of the vehicle.

A suspension system also maintains the stability of the vehicle in pitching or

rolling when vehicle is in motion.

What is Steering System in automobile?

In front wheels can be turned to left and right by steering system so that the

vehicle can be steered. The steering wheel is placed in front of driver. It is

mechanically linked to the wheels to provide the steering control. The primary

function of the steering system is to provide angular motion to front wheels so that

vehicle can negotiate a turn. It also provides directional stability to vehicle when

the vehicle moves ahead in straight line. Now-a-days, many vehicles are equipped with power steering which uses pressure

of a fluid to reduce steering effort. When driver turns the steering wheel, a

hydraulic mechanism comes into play to provide most of the effort needed to turn

the wheel.

Subscribe to:

Comments (Atom)