Thursday, 10 December 2015

Reason for failures of paints?

1. Not proper cleaning of body before painting

2. Not covering dents or spots

3. Not using of proper good quality paint

4. Not applied the pretreatment with zinc phosphate

Requirements of Good Painting?

2. It should protect the hidden parts also from the corrosion.

3. It should have esthetic appearance.

4. It should be smooth finish for stream lining.

5. It must reduce the aerodynamic drag.

Automotive Painting

The corrosive nature of a metal used in a motor body

construction, necessitate the application of an anti corrosion coating. For this

reason the painting should be done.

Function of Painting:

1. It reduces the corrosion and protect the vehicle

body.

2. It is used for cleanliness.

3. It is used for esthetic appearance.

4. It is used to reduce the friction due to the

aerodynamic drag and allow the vehicle in stream

lining.

5. It is used for identification purpose.

Tuesday, 1 December 2015

Different methods to door lock or unlock mechanisms?

There are different methods to door lock or unlock mechanisms:

1. With a key

2. By pressing the unlock button inside the car

3. By using the combination lock on the outside of the door

4. By pulling up the knob on the inside of the door.

5. With a keyless – entry remote control.

6. By a signal from a control center.

1. With a key

2. By pressing the unlock button inside the car

3. By using the combination lock on the outside of the door

4. By pulling up the knob on the inside of the door.

5. With a keyless – entry remote control.

6. By a signal from a control center.

Torsion Bar in suspension system?

Torsion Bar

Torsion bar suspension is used in independent suspension system. It is a

rod acting in torsion and taking shear stresses only. It is made up of heat

treated alloy spring steel. This bar stores amount of energy nearly as same as

coil spring.

The bar is fixed at one end to the fr4ame, while the other end is fixed to

the end of the wheel arm and supported in the bearing. The other end of the

wheel arm connected to the wheel hub. When the wheel strikes a bump, it

starts vibrating up and down, thus exerting torque on the torsion bar which

acts as a spring.

Stabilizer Bar in suspension system?

Stabilizer is necessarily used in all independent front suspension. It

reduces tendency of the vehicle to roll on either side when taking a turn. It is

simply a bar of alloy steel with arms at each end connected to the lower wish

bone of the independent suspension system. It is supported in bush bearings

fixed the frame and is parallel to cross member. When both the wheels

deflect up or down by the same amount, the stabilizer bar simple turns in the

bearings. When only one wheel deflects, then only one end of the stabilizermoves, thus it acts as a spring between two sides of the independent front

suspension.

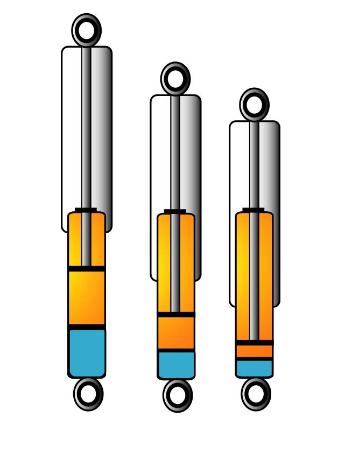

Working of Single acting Telescopic hydraulic shock absorbers?

If the axle eye moves upwards then the fluid must be displaced

from the bottom. Top side of the bottom side fluid through the outer ring of

the piston by lifting the non return valve. But since the increase in the volume

of upper end of the cylinder is less than the volume of the lower end. Fluid will

also displaced through the inner ring of holes of non return valve of foot

valve, and the level at the fluid will raise in the reservoir. The pressure setup will

depend on the size of hole in the piston and Foot valve and the squire of the

speed of which the cylinder is moved.

For downward motion of the cylinder the fluid will be displaced form

the upper end of the piston. In the leaver end through the inner ring of hole of

non return valve in the piston. The fluid will also be draw in the lower end of

the cylinder from the reservoir to the outer ring of hole of non return valve of

the foot valve.

Fig of shock absorber

Need of Shock Absorber?

If the suspension springs are rigid enough, they will

not absorb road shocks efficiently, and if they are flexible enough, they will

continue to vibrate for longer time even after the bump has passed.

Therefore, the springing device must be compromise flexibility and stiffness a

shock absorber needed in Automobile Suspension system.

Helper Springs?

The helper springs are used in heavy vehicles for rear suspension. When

vehicle fully loaded the main spring as well as helper spring to come in

action and absorb the road shocks. When the load of the vehicle is less the

helper spring will not act and the main spring only absorb the road shocks.

Subscribe to:

Comments (Atom)